Integrated Document No. 10/VBHN-BCT dated January 23, 2014 of the Ministry of Industry and Trade integrates the Decisions on promulgating the regulation on preservation and abandonment of petroleum grilling wells

ATTRIBUTE

| Issuing body: | Ministry of Industry and Trade | Effective date: | Updating |

| Official number: | 10/VBHN-BCT | Signer: | Vu Huy Hoang |

| Type: | Consolidated Text | Expiry date: | Updating |

| Issuing date: | 23/01/2014 | Effect status: | Known Please log in to a subscriber account to use this function. Don’t have an account? Register here |

| Fields: | Industry |

THE MINISTRY OF INDUSTRY AND TRADE

Integrated Document No.10/VBHN-BCT datedJanuary 23, 2014 of the Ministry of Industry and Trade integrates the Decisions onpromulgating the regulation on preservation and abandonment of petroleum grilling wells

Decision No. 37/2005/QD-BCN dated November 25, 2005, of the Minister of Industry, on promulgating the Regulation on preservation and abandonment of petroleum drilling wells, coming into effect on December 29, 2005, corrected by:

Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and abandonment of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, of the Minister of Industry, coming into effect on February 24, 2006.

Pursuant to the July 06, 1993 Petroleum Law and the June 09, 2000 Law amending and supplementing a number of Petroleum Law;

Pursuant to the Government’s Decree No. 48/2000/ND-CP, dated September 12, 2000, detailing implementation of Petroleum Law;

Pursuant to the Government’s Decree No. 55/2003/ND-CP dated May 28, 2003, defining the functions, tasks, powers and organizational structure of the Ministry of Industry;

At the proposal of Director of Energy and Petroleum Department,1

DECIDES:

Article 1.To promulgate together this Decision the regulation on preservation and abandonment of petroleum grilling wells.

Article 2.This Decision takes effect 15 days after publishing on the Gazette. The previous provisions in contrary to this Decision shall be annulled.

Article 3.The Chief of ministerial office, the Chief Inspector of Ministry, Directors of Ministry, Directors of provincial/municipal Department of Industry, General Director of Petroleum Corporation and heads of relevant units shall implement this Decision.

Certification of Integrated Documents

The Minister

Vu Huy Hoang

REGULATION

ON PRESERVATION AND ABANDONMENT OF PETROLEUM GRILLING WELLS

(Promulgated together with Decision No. 37/2005/QD-BCN dated 25/11/2005 of Minister of Industry)

Chapter 1.

GENERAL PROVISIONS

Article 1.Scope of adjustment

This regulation is promulgated aiming to protect natural resources and natural structure of soil, prevent acts leading creation of obstacles ortamperingof marine environment status as well as mainland environment status when carrying out activities involving preservation and abandonment of petroleum drilling well.

Article 2. Scope of application

This Regulation is applies to activities involving preservation and abandonment of drilling wells which are drilled or managed by mangers or organizations, individuals (hereinafter collectively referred to as operators) during performing activities of petroleum research, survey and exploitation in territory,exclusive economiczones and continental shelves of the Socialist Republic of Vietnam.

Article 3. Interpretation of terms

In this Regulation, the below terms are construed as follows:

1. “Well preservation” means reinforcement of buttons and install equipment in wells aiming to ensure for drilling wells to be safe in a defined term and then operations of survey, drill stem test, exploitation may be continuedfavorably.

2. Cement retainer means an instrument used in the course of cement pressure pump at high pressure in order to temporarily isolate cement flows up, down on drilling wells.Cement retainer is a closed instrument, cannot withdraw but made of metal which is able to drill out.

3. “Temporary orientation” is a steel framework laid on sea bed aiming to orientate for drilling set and conductor pipe with bid diameter; support subsea equipment and create points to brace guide cables in wells having underground well-head.

4. “Well abandonment" means reinforcement of cement plugs, laying of bridge plugs, cutting for removal and withdrawal of some pipe sections in drilling wells, clearing of obstacles surrounding wellhead.

5. "Well ending” means abandonment or preservation of a well or a part of a petroleum drilling well.

6. “Shooting section” means any section of well which has propped by pipes, shot for holes to create the circulation between wall of system and inside of well or in the middle of various casing pipe layers.

7. “Cement plug” means a quantity of cement mortar which is pumped into drilling well to a defined depth in order to create a hard and solid cement block aiming to isolate various reservoirs parts along drilling well.

8. “Bridge Plug” means an instrument to isolate inside well which is made of metal and rubber, easy to be drill up, often used to isolate various distance inside well already been propped with pipes.

9. Petroleum Corporation of Vietnam (international transaction name is PETROVIETNAM) is a state-owned enterprise which is established by Vietnam Government in order to conduct petroleum activities and conclude into petroleum contracts with organizations and individuals conducting petroleum activities under the Petroleum Law.

10. “Emergency case” includes the following events:

a) Any serious influence of natural elements or disaster such asthunder,storms,cyclones, earthquakes.

b) Fire, explosion, accidents, malfunction, broken of means, machinery, collapse, abandonment of structure.

c) Epidemics or quarantine.

d) Any event or circumstance similar on nature with any aforesaid case.

Article 4. Responsibilities of operators for quality of well ending

The approval of the Ministry of Industry for reports on drilling well ending which are submitted by operators according to Article 8 of this Regulation shall not exclude responsibilities of operators for quality of drilling well ending and consequences on safety and environment arising from those drilling wells, if there are evidences proving such drilling wells have not ended in accordance with this Regulation.

Article 5. Preliminary well-ending plan

In drilling plan of entire mine or each single drilling well, operators must make preliminary well-ending plan after ending drill if these wells have not yet been exploited.

Chapter 2.

PROCEDURES FRO APPROVAL AND CONTENT OF WELL-ENDING PLAN

Article 6. Submission of well-ending plan

Except for emergency cases, before ending the drilling well, operators must send well - ending plan not later than five (05) working days before implementation to the Ministry of Industry for consideration and approval.

Article 7. Content of well-ending plan

A well-ending plan must include but not only limited in the following contents:

1. Reason of ending well

2. Basic figures of drilling well, summary of drilling and completing wells, basic figures of drilling well exploitation and use, quotations of geographical and geo-physical documents of drilling well, result of measuring cementation quality at outer of casing pipe for exploitation, reservoir pressure and documents related to wells or walls of wells which are required to be destroyed or preserved.

3. Structure diagram of drilling well in which clearly stating:Depth of well, depth to put support pipes, height of cement pole in torus space; kind and density of solutions in drilling well and in torus spaces; equipment which is mounted in well.For wells drilled in oblique direction and wells drilled horizontal direction, depth of oblique cutting, vertical depth, depth along wall of wells, angle of inclination and azimuth.

4. Method to mount bridge plugs and cement plugs include way to mount, volume of cement mortar and volume of pumping solutions, distance to mount and depth to mount, method to test pressure and tonnage.For wells subject to abandonment, it is required to clearly state method and depth of cutting pipe.

5. Plan on clearing and exploration surrounding area of drilling wellhead before ending wells, moving or dismantling rid.

6. Time, duration of ending wells, plan on periodical examination for the preserved wells.

7. Reports on environmental protection as prescribed in Article 7 of Regulation on environmental protection in search, exploration, development of mines, exploitation, storage, transport and processing of petroleum and concerned services promulgated together with Decision No. 395/1998/QD-BKHCNMT dated April 10, 1998, of the Minister of science, technology and environment.

Article 8. Well-ending report

1. Operator must make report about the process of ending drilling wells and hand over such documents to the Petroleum Corporation of Vietnam within 21 days after finishing.

2. All figures and documents related to the work of well ending, including diagram of actual status of wells after ending and documents collected when conducting exploration for the final time regarding sea beds, sea surface in area surrounding drilling wells must be enclosed with report of well ending.

Article 9. Cutting wellhead by explosives

1. Except for special cases, operator must use mechanical method to cut, withdraw wellhead.

Special case, if it is required to apply method of cutting wellhead by explosives, operator must submit an implementation plan for the Petroleum Corporation of Vietnam to consider and submit to the Ministry of Industry for approval.

2. When using explosives to cut wellhead and casing pipe.Operator must absolutely abide by safety regulations involving use of explosives and regulations on safety, environmental protection under Vietnamese law and international common practices.

Chapter 3.

WELLS PRESERVATION

Article 10. General requirements

The operator must ensure that any well managed by him, as required for preservation, it must satisfy the following conditions:

1. Inside of wells always is in safe condition even when equipment of wellhead is broken due to malfunction or being removed, wells will maintain isolation between reservoirs with each other and reservoirs with surface.

2. Ability of re-using wells for drilling, research, exploitation, repair and other forms or abandonment of wells is ensured at any time in a most advantaged and safe manner.

3. To decrease to the minimal extent of interference of equipment for surrounding environment.

Article 11. Classification of drilling wells which are required to preserve

Based on conditions of drilling wells which are required to preserve, wells are divided into 3 types:

Type 1: Drilling wells that are required to preserve for a long term (from 3 years or longer), including wells of which research results assume that use and exploitation of wells bring an economic effectiveness but there is no use plan.

Type 2: Drilling wells that are required to conduct temporary preservation (from 1-3 years), including wells stated in exploitation plan but belonging to reserve kind.

Type 3: wells of short-term maintenance (less than 1 year), including wells which are used, temporarily stopped operation for repair or preparation to put into use.

Article 12. Preservation of part inside wells

1. The process of mounting equipment or reinforcing plugs to preserve wells must ensure to be able to control pressure accumulated under plugs before dismantling in the process of re-opening wells.

2. For drilling wells which are required for type-1 preservation, during preservation, the exploitation rod must be drawn from wellhead and cement plugs or bridge plugs are mounted to isolate the opened reservoirs. Method of mounting plugs is similar to method stated in Articles of Chapter IV1this Regulation.

3. Drilling wells of type-2 preservation are allowed to let the exploitation rod set in wells like as status of being exploited.During preservation, wells must be in status of being filled up with solutions used for well preservation.

4. Drilling wells of type-3 preservation, they are allowed to keep intact all status of wells, example: valves must be closed tightly and cranks of valves are dismantled (except for underground wellhead).

Article 13. Solutions to preserve drilling wells

The operator must ensure that when a part or entire well is required to be preserved in type 1 and type 2, such wells must be filled up with solution with density which is enough to control the reservoir pressure existing in drilling wells before conducting operations of preserving well.Preservation solutions must be processed to prevent equipment from corrosion.

Article 14. Preservation of underground wellhead

1. For wells with wellheads laid under sea, the orienting cable system must be cut and revoked before moving drilling rig out from position.

2. The inside of wellhead of preserved wells or completed wells has to be processed against corrosion and outside of wellhead must be protected to prevent damages due to impact and be equipped means that allow to determine position of wellhead easily.

3. To avoid danger for wellhead and instruction pole as well as vessels and fishers going around, the operator must place buoys to warn about underground drilling wells which are preserved at water areas under depth of 20m.

Article 15. Preservation of wellheads on surface

1. Wells which are exploited, preserved on fixed rigs must be installed Christmas tree on top of the wellhead.All handles except examination valve must be dismounted. Branch pipelines, pressure gauges for depression, examination must be dismounted and must have blind flange, plugs installed in pipe plugs, pressure gauge base. On the top of wellhead must mount a signboard size of 0.4 x 0.2 m, inscribing name of mine, well, name of the operator in charge of preservation, beginning time of preservation, reason and duration of preservation.

2. The drilling wells exploited on mainland need be preserved similar to wells stated at Clause 1 Article 152. In addition to, these drilling wells are also protected with a fence made ofreinforcedconcrete, size of4m x 4m x 2m, on fence, mounting a signboard, size of 0.4m x 0.2m, inscribing name of mine, well, the operator in charge of preservation, the beginning time of preservation and duration of well preservation.

Article 16. The examination frequency of the preserved wells

The operator shall examine the preserved wells with the frequency as follows:

- Annually, for wells which are required type-1 preservation

- Quarterly, for wells which are required type-2 preservation.

- Monthly, for wells which are required type-3 preservation.

Article 17. Duration of preservation

The operators shall put wells which are required to be preserved for a long term into exploitation or destruct such wells within six (06) years from the date of preservation, unless the Ministry of Industry has accepted for extension of well preservation.

Chapter 4.

ABANDONMENT OF WELLS

Article 18. General requirements

The abandonment of wells must ensure the following requirements:

1. After a well is destroyed, it must ensure to maintain the integrity of inside of wells, not to happen circulation of fluids between structures or with surface of sea beds, water surface or mainland when counter-pressure equipment or Christmas tree on the top of wellhead has been dismounted or moved.

2. After finishing abandonment of wells, area of sea beds or surface surrounding a drilling well must be cleared, not let any obstacle or make the initial status of natural environment disturbed.

Article 19. Cutting, withdrawal of casing pipes, wellheads

1. The operator are not permitted to withdraw any casing pipe which has been laid in inside of wells unless it has been approved in writing by Petroleum Corporation of Vietnam and process of withdrawal must be performed in accordance with provisions of this Regulation.

2. All wellheads must be cut and withdrawn.The minimal depth of cutting is 3m under the ground or sea beds, in special case; it must send report to Petroleum Corporation of Vietnam for consideration and decision.

3. When cutting pipes it must pay attention to the following points:

a) If the overlapping section of two casing pipes is not cementing pump, the inside casing pipe may be cut and withdrawn.Depth of cutting pipe is based on height of cement pole in torus spaces, which is defined through documents of measuring geo-physical properties of drilling wells.

b) In case of being able to exist odd pressure in torus spaces outside casing pipes, it must chip casing pipe adjoining the below part of wellhead and must contain the control of well by counter-pressure equipment before and during cutting pipes.

c) Before cutting pipes, density of fluids in drilling well must be corrected in line with durability of stratum at pipe base in front of it.

d) It must cut and withdraw each pipe separately.Do not cut, withdraw two (02) casing pipes (or more) at a same cutting, except for surface casing pipe.

Article 20. Position of plugs in bare section of wells

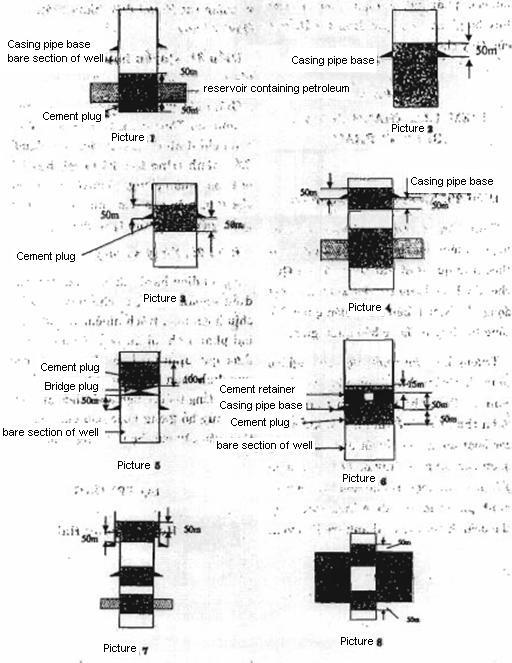

1. Reservoirs containing petroleum, reservoirs with abnormal pressure or reservoirs causing lost of fluids in bare section of wells must be isolated by cement plugs covered for entire such reservoirs adding 50m on the top and 50m at the bottom of such reservoir (Appendix - picture 1).

2. If bare section of wells has length less than or equal to 250m and diameter less than 215.9mm (8-1/2inch), it must lay cement plugs at position higher than the deepest casing pipe base 50m from bottom of wells (Appendix – picture 2).

3. If bare section of wells has length more than 250m (>250m) and reservoirs in such section of wells do not contain gas or have no abnormal pressure, only lay a cement plug with length of 100m covering 50m above and 50m below the deepest casing pipe base (Appendix – picture 3).

4. If bare section of wells has abnormal pressure or reservoirs containing petroleum and drilling sets, drilling rods, casing pipes and other instruments are jammed in that, the above equipment must be withdrawn to make clearance for the are section of well to the ultimate level and bury, destroy such bare section of wells in accordance with clause 1 Article 203of this Regulation.

Article 21. Position to lay plugs in well sectionswhich have propped by pipes

1. In order to isolate section of well which has propped by pipes with bare section of well, it must lay a balance cement plug with length not less than 100m covering 50m above and 50m below the deepest casing pipe base (Appendix – picture 4).

2. In case where conditions of inside of drilling well are not allowed isolating efficiently by balance cement plug, it may apply one of following methods:

a) Method of using bridge plug:To lay a bridge plug under casing pipe base in distance of 50m and a cement plug with minimal length of 100m must be laid above bridge plug (Appendix - picture 5.)

b) Method of using Cement Retainer:Casing pipe base mat be isolated by placing an instrument to hold cement at a distance of 50m from casing pipe base, then conduct the cement pressure pump through this instrument. Volume of cement mortar must ensure to create a 100m-long cement plug under Cement Retainer, then placing a cement plug with minimal height of 15m above Cement Retainer (Appendix – picture 6).

c) If a cement plug is used to isolate the overlapping section of floating plug of pipe with previous pipe base, this cement plug must have minimal length of 100m and be placed at distance of 50m above and 50m below in comparison with position to hang floating casing pipe (Appendix – picture 7).

d) In case of propping pipe through salt reservoir or drift sand (drift reservoir), to prevent case where casing pipe is distorted because reservoir is able to flow, cement plug must be placed through space of drift reservoir to prevent pressure from the outside.If a reservoir is able to flow over 200m, it must place two cement plugs minimally, one plug is placed through boundary of bottom and one plug is placed through boundary of top of such drift reservoir (Appendix – picture 8).

Article 22. Abandonment of drilling well section which has been shot to open reservoir

If well shot to open reservoir, opened space of reservoir must be isolated orderly by bridge plugs or both bridge plugs and cement plugs if distance is allowed.The construction process must be performed under one of the following methods:

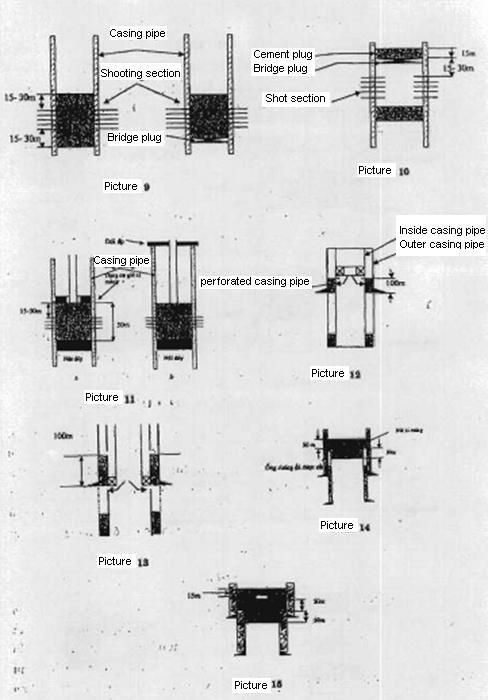

1. Method of pumping cement for replacement:To place a balance cement plug crossing the shooting section and prolong 15-30 m above and 15-30m below from the shooting section to the nearest bridge plug (Appendix - picture 9).

2. Method of using bridge plug:The shot sections may be isolated by placing a bridge plug (or exploitation packer with plug) in scope of 15-30m from top of the shot section and a cement plug with length not less than 15m must be placed above this bridge plug (Appendix - picture 10).

3. Method of cement pressure pump:To isolate reservoirs with abnormal pressure and prevent fluids flowing between reservoirs and behind of casing pipe, the shot section must be pumped cement pressure.The process of pressure pump must be perform by pumping cement in the shot section through an Cement Retainer placed above the shot section at least 15m (Appendix – picture 11a) or a rod set associated with counter-pressure equipment (Appendix – picture 11b).Concurrently, it must leave at least 25m cement on any pressure pump instrument which is placed in wells.

Article 23. Measures to amend and supplement

1. Chiseling pipe and pressure pumping:To prevent circulation of fluids between reservoirs and torus spaces, it must have 100m cement with good adhesion minimally inside of previous pipe base.If not having, the last inside casing pipe must beperforated at depth of 100m above pipe base before it and volume of cement mortar equivalent to 100m torus space must be pressed through the perforated section by Cement Retainer or packer with pressure not more than pressure to break reservoir (Appendix – picture 12).

2. Chiseling pipe and circulation:If method of pressure pump cannot be performed due to the allowed safe pressure limitation of casing pipe, it must chisel the inside casing pipe adjoining the below part of previous casing pipe and perform cement pressure pump up to 100m of torus space inside of theperforatedsection (Appendix – picture 13).

3. Theperforated points as described in Clauses 1 and 2 this Article shall be cemented like the shot sections in Article 14.

Article 24. Placing plugs in case of cutting pipe

1. When cutting pipe for withdrawal as prescribed at clauses 2 and 3 article 194, the cut plugs of casing pipes must be isolated under one of methods:

a) Method of cement plug for replacement:A 100m balance cement plug shall be used to isolate plug of pipe and prolong 50 m above and 50 m below from the cut plug of pipe (Appendix - picture 14).

b) Method of cement pressure pump:To place an instrument to hold cement in a bigger casing pipe at distance of 50m above the cut plug of casing pipe and conduct cement pressure pump through instrument for pressure pump.Volume of cement mortar must ensure to fill up 100m casing pipe below instrument of pressure pump (50m inside and above of the cut plug of casing pipe and conduct the cement pressure pump through instrument for pressure pump.Volume of cement mortar must ensure to fill up 100m casing pipe below instrument of pressure pump (50m inside and above of the cut plug of casing pipe) and 15m above Cement Retainer (Appendix – picture 15).

2. Before cutting and withdrawing surface casing pipe and conductor pipe, it must place a bridge plug in surface pipe at depth of 200m under sea beds for offshore drilling wells or under rotary table for drilling wells on mainland.A cement plug with 100m surface shall be placed on top of that bridge plug.

3. For drilling plugs on mainland, the cut plugs of surface pipe and conductor pipe must be filled with cement and leveling foundation of drilling well to turn the initial natural situation and at position of well, it must place a steel signboard, size of 0.4m x 0.2m, clearly writing name of mine, name of drilling well, name of operator and date of abandonment.

Article 25. Requirements involving plug test

1. Checking position and load test of cement plug:

a) It must wait not less than six (06) hours for congealing of cement plug, then place instrument kit down to determine position of cement plug and use a tonnage of not less than 10 tons to check the accuracy of position and precipitate quality of cement plugs.

b) If a cement plug is placed off the tentative position or fails to bear load test, it must place other cement plug to replace and then it must re-determine position and test load of new cement plug in way stated at point a above.

2. To affirm isolated situation of bare section of well under the deepest casing pipe base, cement plugs and bridge plugs as stated at Clauses 2 and 3 Article 205must be test pressure to value higher than test pressure for receipt of reservoir at pipe base 3450 KPa (500psi) for 15 minutes.

3. Cement plugs and bridge plugs as stated at Clauses 1, 2, 3 and 4 Article 216must be tested pressure up value higher than test pressure for receipt of reservoir at casing pipe base 3450 KPa (500psi).

4. Cement plugs and bridge plugs as stated at Article 227must be tested pressure up value higher than reservoir pressure of space tested for reservoir 3450 KPa (500psi).

5. Cement plugs as stated at Clause 1 Article 248must be tested pressure up value higher than test pressure for receipt at the next casing pipe base 3450 KPa (500psi).

6. Condition for plugs to satisfy requirement on pressure test is the pressure test is not reduced more than 10% during 15 minutes of pressure test.

Article 26. Solutions used in abandonment of wells

1. When a part of well or entire well is destroyed, well must be filled up with solution with a density that is sufficient to ensure for control of pressure existing in system before conducting operations involving abandonment of well.

2. Solution in drilling well must be processed to prevent corrosion for casing pipe.

3. For bare sections of well, before cementing, it must place a plug of buffer solution with high viscosity to prevent sediment cement under bottom of drilling well.

Article 27. Cement used in abandonment of wells

Cement used to place any cement plug in drilling well must have minimal pressure durability of 3000KPA after cement has been congealed in duration of (08) hours.

Article 28. Sea bed exploration when destroying wells

The operators must ensure that after destroying a drilling well, sea bed area surrounding top of drilling wellhead must be surveyed carefully to sure that all obstacles have been cleared.The last documents of sea bed survey must be enclosed report on destroying wells as prescribed in Article 8 of this Regulation.

Chapter 5.

EXAMINATION, INSPECTION AND HANDLING OF VIOLATION

Article 29. Examination and inspection

Petroleum Corporation of Vietnam has right to conduct regular examinations with frequency as prescribed in Article 199of this Regulation or irregular examinations over activities of the operators involving abandonment or preservation of wells.

In necessary case, the Ministry of Industry shall assume the prime responsibility for, and coordinate with Petroleum Corporation of Vietnam in establishing inspectorate team to examine, inspect activities of the operators involving abandonment or preservation of wells.In all cases, the operators must facilitate for examination and inspection teams to complete task.

Article 30. Supervision of implementation

The Ministry of Industry and Petroleum Corporation of Vietnam shall guide and supervise the operators in compliance with this Regulation.

Article 31. Powers of supervisors

Standing supervisors on the field who are appointed by Petroleum Corporation of Vietnam have right to request the operators to present plans on abandonment or preservation of wells, have right to supervise implementation during abandonment or preservation of wells in compliance with this Regulation.

Article 32. Handling of violation

The operators who fail to comply with this Regulation shall take all responsibilities for arising damages, be sanctioned at penalties prescribed in the Petroleum Law and current regulations of Vietnamese law, and have obligations to re-perform the abandonment of well or preservation of well at the request of the Ministry of Industry.

The Minister of Industry and Trade

Hoang Trung Hai

APPENDIX

DIAGRAM DECRIBING THE ENDING OF WELLS

1Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and destruction of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, of the Minister of Industry, having grounds for promulgation as follows:

“Pursuant to the Government’s Decree No. 55/2003/ND-CP dated May 28, 2003, defining the functions, tasks, powers and organizational structure of the Ministry of Industry;

Pursuant to the November 12, 1996 Law on promulgation of legal documents; the December 16, 2002 Law amending and supplementing a number of articles of Law on promulgation of legal documents;

Pursuant to the Government’s Decree No. 104/2004/ND-CP dated March 23, 2004, onthe official gazette of the Socialist Republic of Vietnam;

At the proposal of Director of Energy and Petroleum Department,”

2Article 2 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and destruction of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006, stipulated as follows:

“Article 2.This decision takes effect on the day of its signing.

The Chief of ministerial office, the Chief Inspector of Ministry, Directors of Ministry, Directors of provincial/municipal Department of Industry, General Director of Petroleum Corporation and heads of relevant units shall implement this Decision.”

1Phrase “Chapter III” is amended by phrase “Chapter IV” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and destruction of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

2Phrase “Article 26” is amended by phrase “Article 15” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and destruction of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

3Phrase “Article 12” is amended by phrase “Article 20” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and abandonment of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

4Phrase “Article 11” is amended by phrase “Article 19” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and abandonment of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

5Phrase “Article 13” is amended by phrase “Article 219” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and abandonment of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

6Phrase “Article 12” is amended by phrase “Article 20” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and abandonment of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

7Phrase “Article 14” is amended by phrase “Article 22” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and abandonment of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

8Phrase “Article 13” is amended by phrase “Article 24” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and abandonment of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

9Phrase “Article 27” is amended by phrase “Article 16” according to Article 1 of Decision No. 399/QD-BCN dated February 24, 2006, of the Minister of Industry, on correcting the Regulation on preservation and abandonment of petroleum drilling wells, promulgated together with Decision No. 37/2005/QD-BCN dated November 25, 2005, coming into effect on February 24, 2006

VIETNAMESE DOCUMENTS

Consolidated Text 10/VBHN-BCT PDF (Original)

Consolidated Text 10/VBHN-BCT PDF (Original)This utility is available to subscribers only. Please log in to a subscriber account to download. Don’t have an account? Register here

Consolidated Text 10/VBHN-BCT DOC (Word)

Consolidated Text 10/VBHN-BCT DOC (Word)This utility is available to subscribers only. Please log in to a subscriber account to download. Don’t have an account? Register here

ENGLISH DOCUMENTS

Consolidated Text 10/VBHN-BCT DOC (Word)

Consolidated Text 10/VBHN-BCT DOC (Word)This utility is available to subscribers only. Please log in to a subscriber account to download. Don’t have an account? Register here